Time:2019-12-18

Trends and Insights: Just two days ago, the 2019 iREX (Japan International Robot Exhibition) concluded. From December 18th to 21st, 637 exhibitors from 16 countries and over 130,000 professional visitors gathered at Tokyo Big Sight in Koto Ward, Tokyo, to witness the world's largest professional robotics exhibition.

Compared to the China Industrial Expo held in Shanghai in September, iREX saw industrial giants pulling out all the stops, showcasing their true strength. The four major industrial robot brands—ABB, KUKA, Yaskawa, and FANUC—along with comprehensive industrial conglomerates such as Kawasaki, Mitsubishi, Nachi-Fujikoshi, Omron, Epson, Denso, and Toyota—all participated. The exhibition showcased everything from mature product lines to AI applications and cutting-edge explorations of new technologies and scenarios, creating a truly impressive display. As "machine replacement" in industrial and other scenarios is increasingly becoming a hot spot for investment and innovation in the Chinese market, high-level exhibitions such as iREX are an excellent window into cutting-edge trends in the field of robotics.

The Wall of Hardware: Delving deeper into the iREX booths, the disparity became more tangible—the overall pressure of appearance gave way to awe-inspiring details. To put it in a Japanese, chuunibyou way, it was that day when Chinese industry professionals finally remembered the fear they once felt at the mercy of developed industrial conglomerates. The main manufacturers (those who produce industrial robots) displayed an overbearing, domineering style. Compared to the Shanghai Industrial Expo in September, where international manufacturers also made a splash, iREX saw manufacturers going full throttle, truly flexing their muscles. Many companies' robots ran at significantly higher speeds at iREX. This undoubtedly posed additional challenges to preparation, but companies were relentless, for the iREX show, where everyone was on full throttle, demanded their highest level of effort.

Nachi Fujikoshi simply brought in a complete set of robotic arms for automated automotive welding, demonstrating the industrial aesthetics of this most mature application direction of robots.

A popular Kawasaki demonstration with children involved taking a photo while the robot painted a picture on a balloon. While this demonstration lacked practical application, it cleverly demonstrated both force control (repeatedly touching a balloon without breaking it) and a degree of visual ability. Furthermore, nearly all major robotic arm manufacturers exhibited force control applications, such as assembly and polishing.

Most impressively, FANUC also brought the world's largest robotic arm, reaching a height of 6.2 meters when fully extended and capable of lifting a maximum weight of 1,700 kilograms. To demonstrate the power of this massive machine, FANUC even borrowed half an Airbus A380 engine from the aviation parts company Safran. The massive robotic arm, wielding an equally massive engine component, soared and flipped through the air, creating a truly breathtaking experience.

The gap in intelligence: At iREX, in addition to the impressive display of industrial infrastructure strength, the wave of innovation in AI and intelligence cannot be ignored. FANUC's "AI Good/Failure Determination" showcased the application of AI in industrial inspection.

Yaskawa's cargo classification scene.

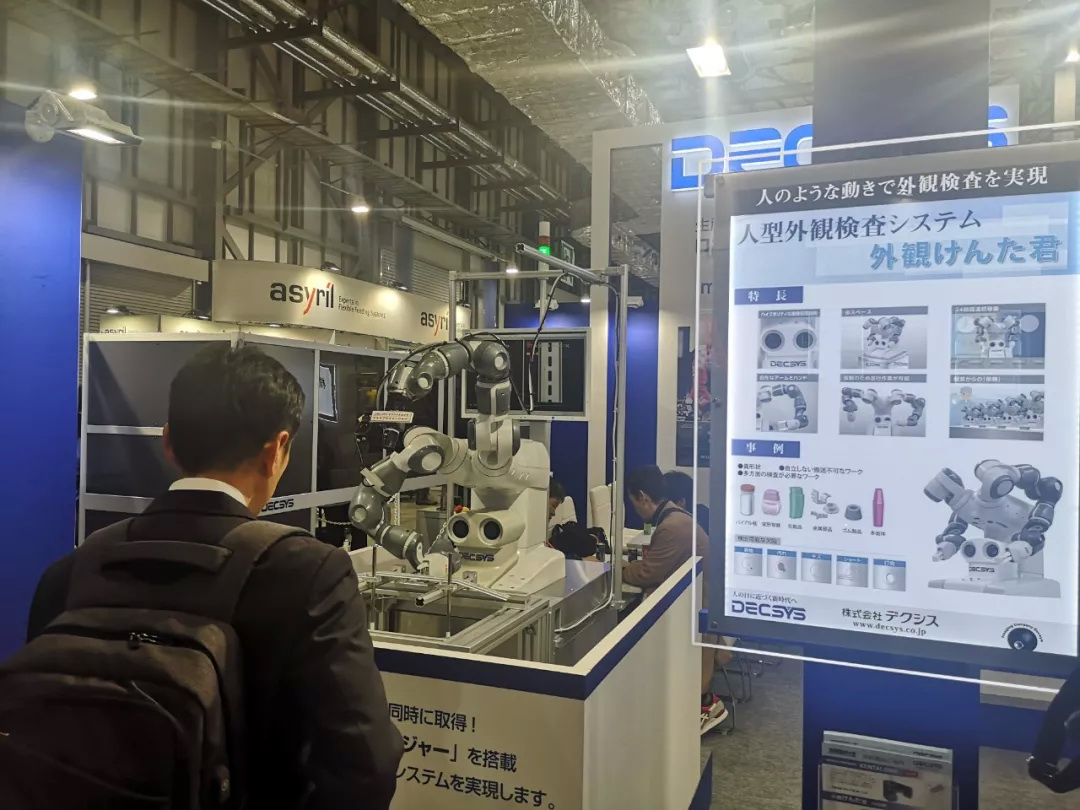

DECSYS's dual-arm robot for appearance inspection.

The 18th China International Door Industry Exhibition

In the golden autumn season, CURVE and Wharton participated in the 18th China International Door Industry Exhibition.

2019-03-18

Office Relocation

At the beginning of the new year, CurveRobot celebrated a relocation. Our headquarters relocated to the Shangyi Cultural and Creative Park on Chaoyang North Road in Chaoyang District. The new campus offers beautiful surroundings and convenient transportation. It borders Liangmachang Park and Chaoyang Joy City to the west, and Baijialou Bridge on the East Fifth Ring Road to the east. We welcome the new year with a fresh new look. We wish the company continued progress through the hard work and unity of all CURVE employees.

2019-01-02

Curve Intelligence Technology has reached a strategic cooperation with South Korea's LXJ Group, marking the debut of China's smart body and paint robots in the Korean market

Today, Cloud Curve (Taizhou) Robot Co., Ltd. (hereinafter referred to as "Curve Robot"), a global leader in intelligent sheet metal spraying technology, officially signed an agency agreement

2025-06-10